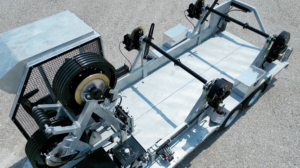

2RT Bullwheel Tensioner

2RT 142 – 8KE /38″ Dual Bull Wheel Tensioner

CAPACITY:

18,800# GVWR-Calculated at 15% Weight Transfer to Tow Vehicles

9,000# Approx. Load Capacity

AXLES:

8,000# Tandem Torflex Axles

12-1/4 x 3-3/8″ Electric Brakes on All Wheels

(4) Four -215/75R/17.5 LR-H Tires, Single Wheel Application

(4) Four- 17.5″ x 6.75″ Single Wheels (8 Holes on 6 1/2″ Bolt Circle)

(1) Pair Mud Flaps

REEL RACKS:

(2) Two – 84″ Dia x 60″ Wide

(2) Two – 2 7/8″ Reel Bars with Crossarm and (1) One Locking Collar

*Cross-Arm adapters offered for various width reels.

(2) Tailing Tensioning Brake Assemblies:

16″ x 3/4″ Aluminum Brake Disc.

Hub, Shaft and Disc Machined as One Unit

M100 Series Hayes Brake Caliper, 10,000 lbs. of Clamping Force

Easy Replacement Non Asbestos Brake Pads

Available 4,100 ft. lbs. Torque

Heavy Duty Bearings

BULL WHEEL TENSIONER:

5,000 lbs. Tension Rating

0-4 MPH

38″ Dual Bull Wheels (Bottom of Groove)

20″ Brakes

Hydraulic Actuation

Replaceable Elastomer Segments

Number of Grooves: 5

Groove Diameter: 1.5″

Operating Controls Are Located Off Ground with Operator Seat And Safety Screen

*Upper and lower Nylatron rollers to ensure conductor stays in bull-wheel groves

(2) Cable Gathering Entry Windows for left and right hand lay conductor.

*Overhead canopy above operator’s station

TONGUE, HITCH & JACK:

5″ x 3″ Tubular Steel A-Frame

6-Position Adjustable Hitch Plate (14″ through 27″)

3″ Lunette Eye set at 27″

3/8″ x 36″L Galvanized Safety Chains with Safety Hooks and Anchor Shackles

(1) One Bolt on – Heavy Duty 12,000# Dropleg Jack

(2) Two Pinnable Drop Leg Jacks Both Sides Located at Rear of Trailer Stabilizing

MAIN FRAME:

5″ x 3″ Tubular Steel Main Frame

5″ x 3″ Tubular Steel Crossmembers at Front of Cargo Bed

6″ x 3″ Tubular Steel Crossmembers at Rear of Cargo Bed

FENDERS:

Fabricated 1/8″ Steel Diamond Tread Plate Fenders

Integrated Constructions with Catwalks

*Stirrup style access step located at operator’s platform

12 VOLT WIRING SYSTEM:

ICC & DOT Approved LED Lights

Sealed Beam Rubber Mounted Stop, Turn, Tail & Marker Lights

S.O. Cable Wiring Loom, Clamped on 16″ Centers with Rubber Lined Clamps

Wiring Loom Terminated in Junction Boxes

Connections Soldered & Sealed with Heat Shrink Tubing

PAINT:

Trailer is Completely Sandblasted

Seams are Sealed with Paintable Caulk

Rust Prohibitive Two-Part Epoxy Polyamide Primer

Two-Part Acrylic Polyurethane Topcoats

All Attachments Painted Before Assembly & Installed with Serviceable Fasteners

Available Options:

Hydraulic Take Up / Pay Out Assembly:

Direct Drive to Reel Bar Eliminates Problems Associated with Rim Drive Systems

2,100 lbs. of Line Pull on a 24″ Drum – 1,800 psi

2,250 psi Continuous / 2,950 psi Intermittent

Double Cross Over Relief Valve to Cushion Motor on Sudden Stops and to Prevent

Overload

SELF-CONTAINED HYDRAULIC POWER PACK:

13HP Honda GX 390 Gas Engine with electric start and recoil back up

20 Gallon Hydraulic Reservoir

Heavy Duty Spin on Type 10 Micron Hydraulic Oil Filter

2,500 PSI – 8 GPM

Fully Hydraulic front and rear jacks

Rear aux. ‘P’ Line shaft w/Level-Wind